Facility managers who have had an electrical fire will often tell you that it came without warning. One minute everything was fine. And the next, sparks were flying out of the electrical panel. However, it’s often possible to know when an electrical disaster could strike. But not with the naked eye. You’ll need an infrared electrical inspection to find the potential culprit.

Facility managers who have had an electrical fire will often tell you that it came without warning. One minute everything was fine. And the next, sparks were flying out of the electrical panel. However, it’s often possible to know when an electrical disaster could strike. But not with the naked eye. You’ll need an infrared electrical inspection to find the potential culprit.

How an Infrared Electrical Inspection Can Protect Your Business

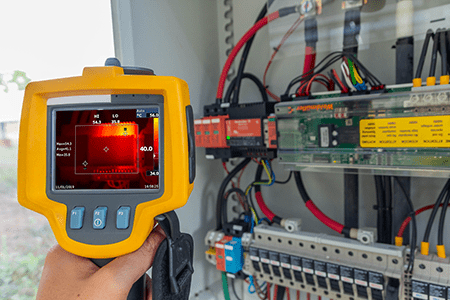

Any object with a temperature over about -450 degrees Fahrenheit emits infrared radiation. With the use of a thermal imager, you can find temperature anomalies that indicate both mechanical and electrical problems. The current flow in an electrical system generates heat. Wiring and different components generate different amounts of heat. When a component is strained, it often overheats.

An inspector with a thermal imager can find an electrical issue before it leads to a fault. Wiring and components that overheat can lead to shorts, melted parts, and electrical fires. Much of an electrical system’s parts and wiring reside behind walls, in ceilings, under floors, and in panels. Inspectors can find overheating components without ripping apart the building or waiting for a problem to come up.

Potential Issues Found with Infrared Electrical Inspection

Wiring Panels. Electrical panels often have dozens or even hundreds of wiring connections. If any single one of these connections is weak or loose, it can begin to overheat. Infrared testing can quickly find where heat inside the panel is coming from and help to isolate and troubleshoot threats.

Pumps and Motors. At points where mechanical and electrical systems come together, there’s always an increased risk for electrical failure. The wiring in pumps and motors can short. And the mechanical components can wear to a point where they start to generate heat, increasing the risk of fire.

Solar Panels. The amount of electricity generated by solar panels is more than enough to cause shorts in the robust cabling used in those systems. Apart from the wiring, the panels themselves can fail and begin to overheat. Eventually, this can cause a short and lead to a fiery catastrophe on the roof.

Find out how to make infrared electrical inspection part of your predictive and preventative maintenance with a free quote from TFP.